Worldwide: Americas Europe/Asia

Industrial Truck Carriages

- Standard hook type carriages are available with class 2, 3 and 4 fork spacing.

- Various widths and design configurations are available to suit the end-use application.

- High visibility designs ensure maximum operator visibility when picking and placing loads.

- Carriage bars are made from high-yield vanadium steel to resist wear and bending.

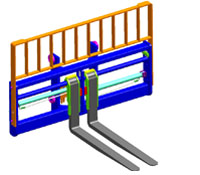

Telehandler Carriages

.

Fixed Carriage

- Various size carriages ranging from 48 to 72 inch widths are available to pick and place materials.

- Carriage capacities are offered up to 10,000 lb.

.

8' Vertical Mast Extension

- Allows the operator to increase placement height without needing additional telescopic boom height.

- Allows the operator to place materials on higher scaffolding sections.

- Quick attach mast mounting to suit the boom mounting interface.

.

Sideshifting and Fork Positioning Carriage

- Allows the operator to position forks precisely in seconds.

- Ideal for handling various load sizes efficiently from the driver’s seat.

- Sideshift allows for more accurate placement of loads in varying site conditions.

.

Side Tilt Carriage

- Tilt loads up to 10 degrees side to side to allow for terrain changes.

- Placement of loads on non-level surfaces such as roofs or picking materials on uneven terrain is possible with side tilt.

Rough Terrain Carriages

.

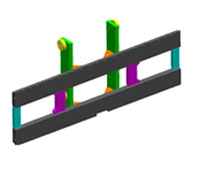

Standard Hook Type Carriages

- Hook type carriages are available for standard ITA class 2 and 3 hook type forks in various widths.

- 70,000 psi yield carriage bar material ensures rigidity and lasting trouble free performance.

.

Pin Type Carriages

- Pin type carriages are available when shaft type forks are required.

- Allows the fork heel to float.

.

Fork Positioning Carriages

- Fork positioning carriages allow the operator to position the forks to the required location for more efficient picking and placement of varying load sizes.

- Shaft type forks are utilized.

Military Carriages

- Lift-Tek military carriages are rugged designs that offer the user multiple control options for positioning the carriage and forks while operating in very demanding conditions.

- Control options include sideshift, fork positioning and oscillation of the carriage.

- Military carriages are engineered and manufactured to adhere to exacting standards of workmanship and performance.

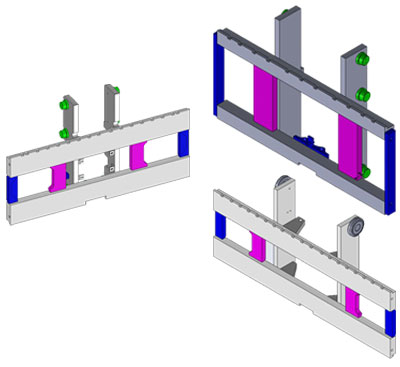

Integral Sideshifters

- Integral sideshifters can provide greater net capacity as the effective thickness of the mast is reduced in comparison to using hang on sideshifters.

- Lift Technologies offers class 2 and 3 integral sideshifters that are reliable designs and are easily maintained.

- Each integral sideshifter is designed to allow the addition of fork positioning as a factory order or in the field if required.

Integral Fork Positioners

- Integral fork positioning can be added to all Lift Tek design integral sideshifters (ISS) with no change in the effective thickness of the complete unit.

- The compact integral design is rated at full capacity with no de-rate required.

- Fork positioning can also be added to a Lift Tek design integral sideshifter in the field as needed – each ISS is pre-drilled to allow easy field installation. Please contact Lift Technologies for more information.